The microwave freeze dryer chamber already has connections

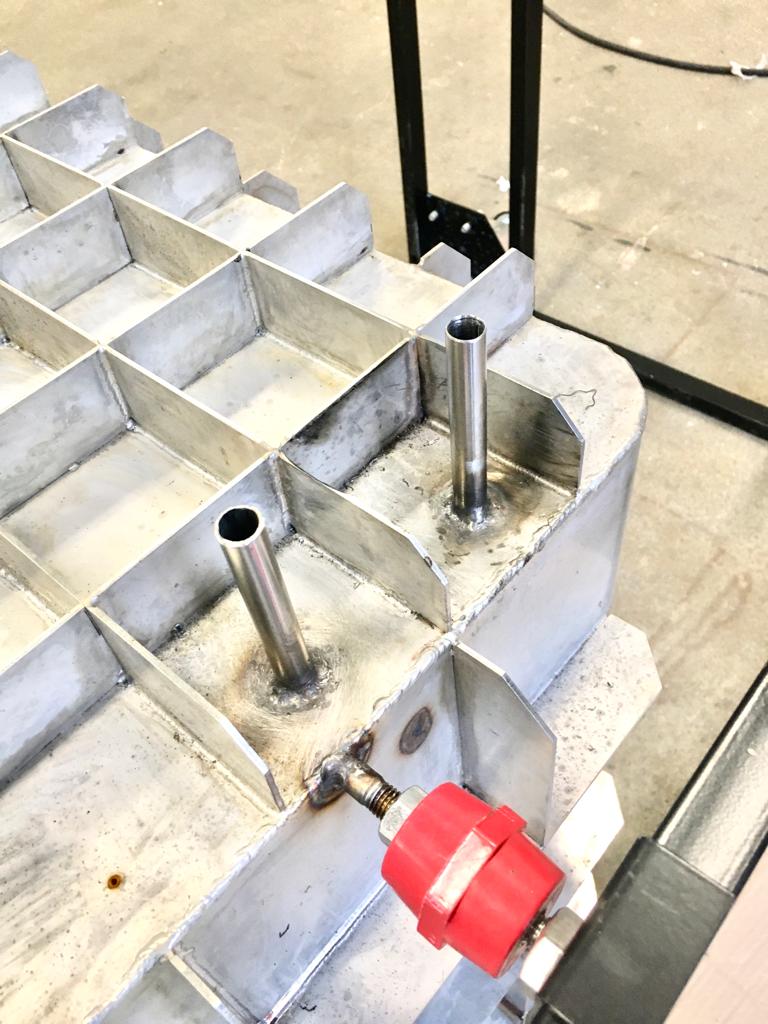

Submitted by ajnowak on Fri, 12/15/2023 - 13:20Today, bushings for connecting the heat exchanger were welded to the microwave freeze dryer chamber.

Today, bushings for connecting the heat exchanger were welded to the microwave freeze dryer chamber.

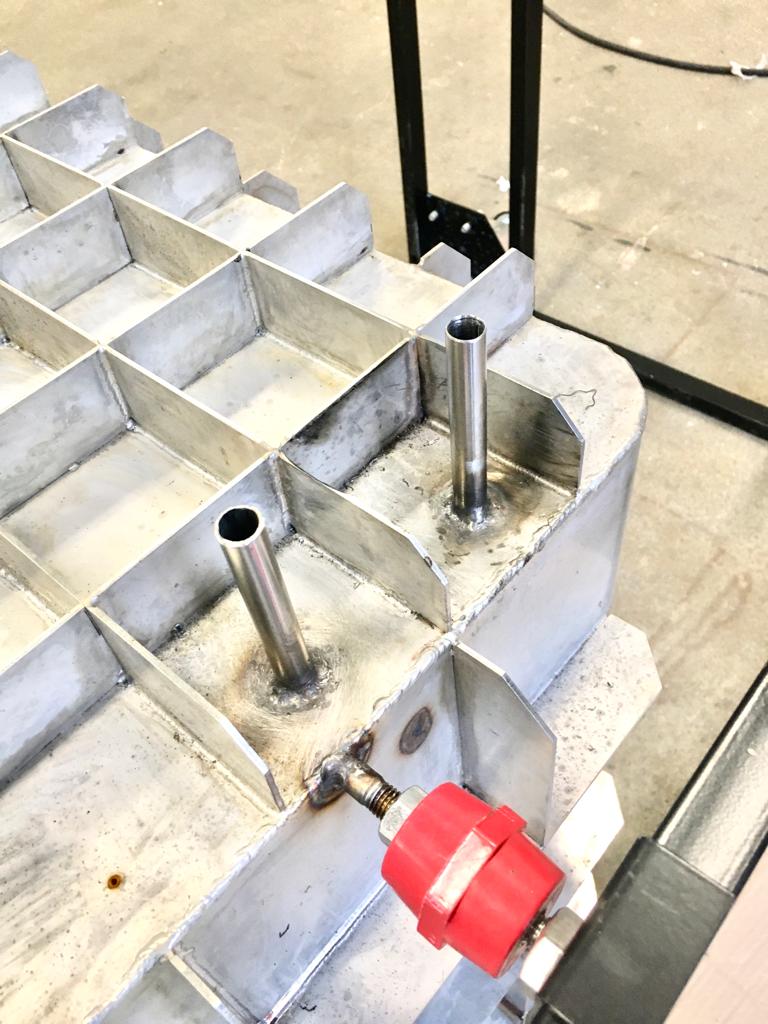

The pins that attach the shelves to the walls of the microwave freeze dryer chamber have already been welded. Fans and circulating element are also installed.

The following work was published in the Journal of Food Engineering:

Edyta Piechnik, J. Smolka, M. Palacz, I. Tolstorebrov, T. M. Eikevik, M. Stebel, M. Haida, A. J. Nowak, A. Ciesielska, J. Bodys, Experimentally validated CFD-tool for a freezing simulation in a small-scale freeze-dryer, Journal of Food Engineering, 2023, 111888, ISSN 0260-8774, https://doi.org/10.1016/j.jfoodeng.2023.111888

Because of the very limited space inside the chamber of the freeze dryer equipped with microwaves, and the resulting difficult assembly work of individual elements, all shelf holders were connected using flat bars. In this way, only these flat bars are attached to the side walls, and not each shelf separately.

The first stage of building the prototype of a freeze dryer equipped with microwaves began at FrostX. The rear wall of the chamber has holes for the magnetrons and the fan motor.

The walls of the chamber were reinforced with fins.

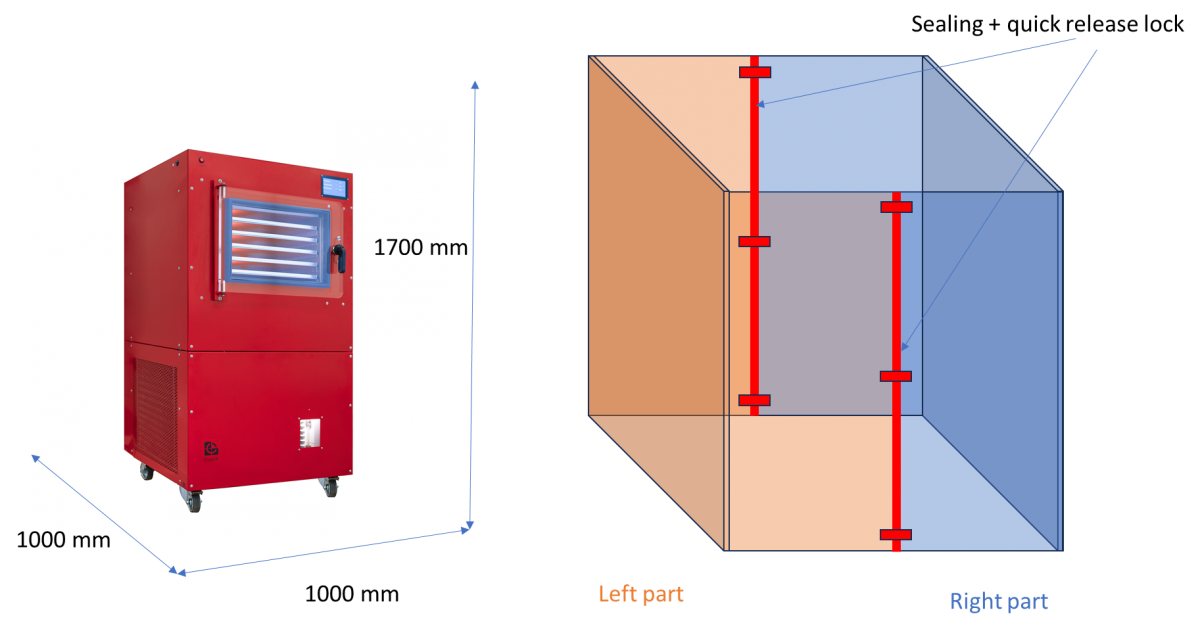

Final tests of the freeze dryer equipped with microwaves will be carried out in labs of SINTEF. For safety reasons the freeze dryer will placed inside protection sleeve equipped with sealing and quick release lock.

The protection sleeve will also be equipped with a side extraction and ventilation duct where gasses can be evacuated.

In July 2022, the WP3 package leader changed - Dr. Michael Bantle left SINTEF, and Dr. Krzysztof Banasiak took his place.

Based on the geometric model of the computational domain shown in the figure below

a simulation model of the lyophilisation process is currently being developed. The computer code generated in the Matlab package is then coupled (at each time step) with the code generated in the Ansys / Fluent package. The obtained numerical results are also compared with the results of thermal measurements.

SINTEF & NTNU are organising The 15th IIR-Gustav Lorentzen Conference on Natural Refrigerants in 2022. Two members from the SINTEF and NTNU teams of our project are actively involved in organisation of this conference. Prof. Trygve M.

The Project Kick-off Conference of the POLNOR 2019 and POLNOR CCS programs took place on June 14 - 15, 2021. Our project was represented by: prof. Jacek Smołka and Edyta Piechnik, MA.