Kato Science Corner x Metrolab GZM.

Submitted by SUT_blog on Mon, 04/22/2024 - 14:15Popular science lecture for the inhabitants of Katowice as part of the Kato Science Corner x Metrolab GZM.

Popular science lecture for the inhabitants of Katowice as part of the Kato Science Corner x Metrolab GZM.

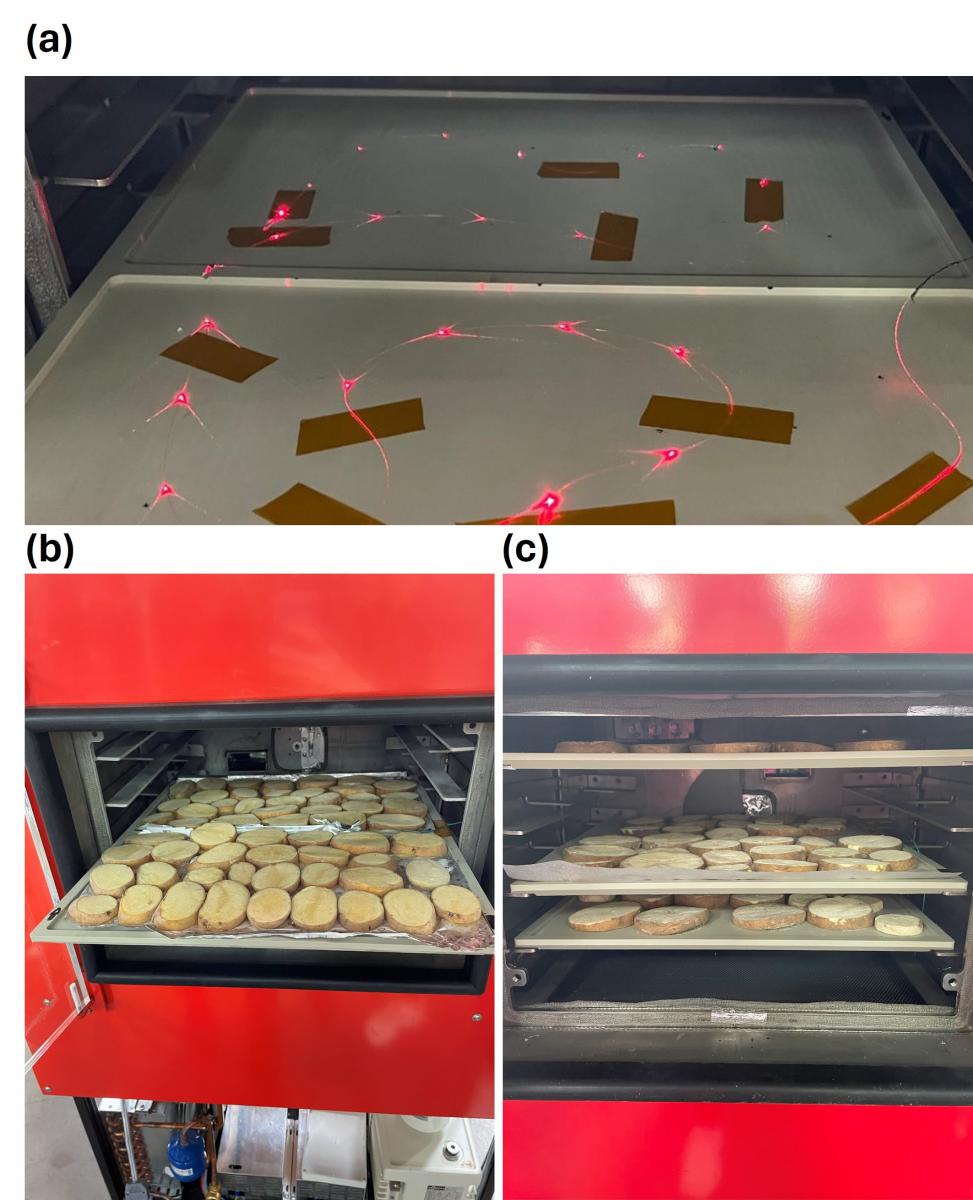

Preparation of the food sample (a) location of the fiber optic temperature sensors on the shelf, (b) placing one-centimeter potato slices on the shelf with fiber optic temperature sensors and (c) placing three trays with products in the chamber

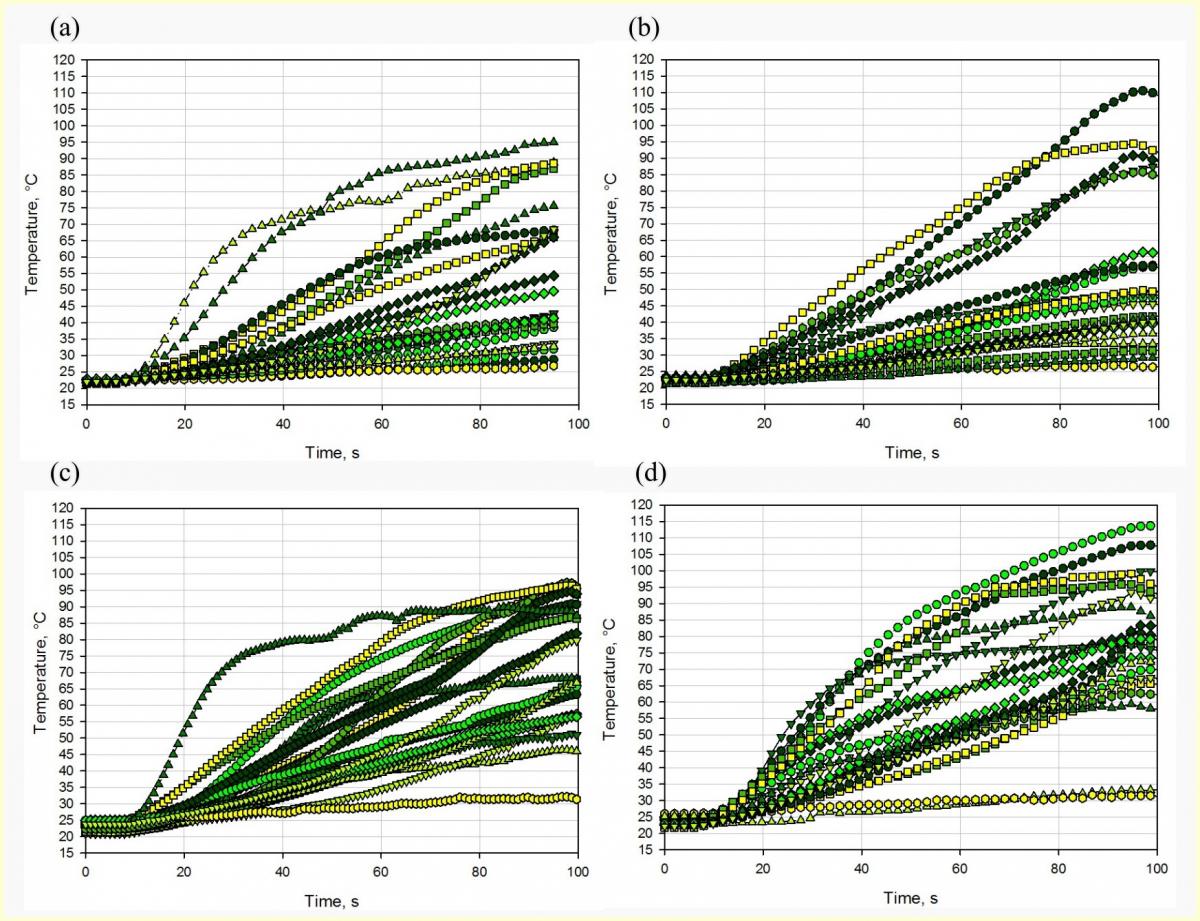

For the prototype chamber, experiments were carried out taking into account four different configurations of magnetron operation (top only, bottom only, both and both with a MW mixer). Fugures below shows the temperature profiles for each analysed configuration and photos of food samples after the process.

The chamber is made of stainless steel, and there are five teflon shelves placed inside, supported on frames on both sides of the chamber (see Fig. below), on which food products can be placed. The location of the shelves relative to the reference chamber remained unchanged. On the back wall of the chamber there are MW windows in through which microwaves enter to the chamber with food products, and MW mixer which ensure uniformity of the MW field.

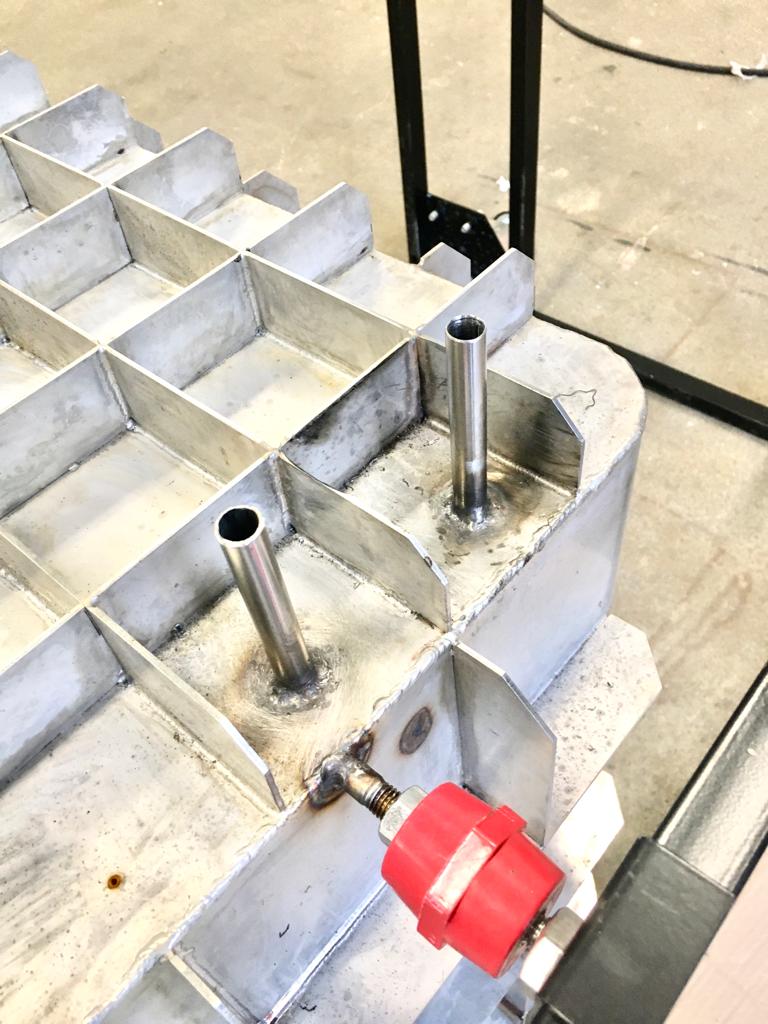

Today, bushings for connecting the heat exchanger were welded to the microwave freeze dryer chamber.

The pins that attach the shelves to the walls of the microwave freeze dryer chamber have already been welded. Fans and circulating element are also installed.

The following work was published in the Journal of Food Engineering:

Edyta Piechnik, J. Smolka, M. Palacz, I. Tolstorebrov, T. M. Eikevik, M. Stebel, M. Haida, A. J. Nowak, A. Ciesielska, J. Bodys, Experimentally validated CFD-tool for a freezing simulation in a small-scale freeze-dryer, Journal of Food Engineering, 2023, 111888, ISSN 0260-8774, https://doi.org/10.1016/j.jfoodeng.2023.111888

Because of the very limited space inside the chamber of the freeze dryer equipped with microwaves, and the resulting difficult assembly work of individual elements, all shelf holders were connected using flat bars. In this way, only these flat bars are attached to the side walls, and not each shelf separately.