Development of novel microwave-assisted freeze-drying unit combined with natural working fluid-based refrigeration system for agriculture and marine foods

| Call: | POLNOR 2019 Call |

| Contract number: | NOR/POLNOR / FrostWave/0029/2019-00 |

| Total budget: | 7 155 824,44 PLN |

| Financed by NCBiR: | 6 571 719,44 PLN |

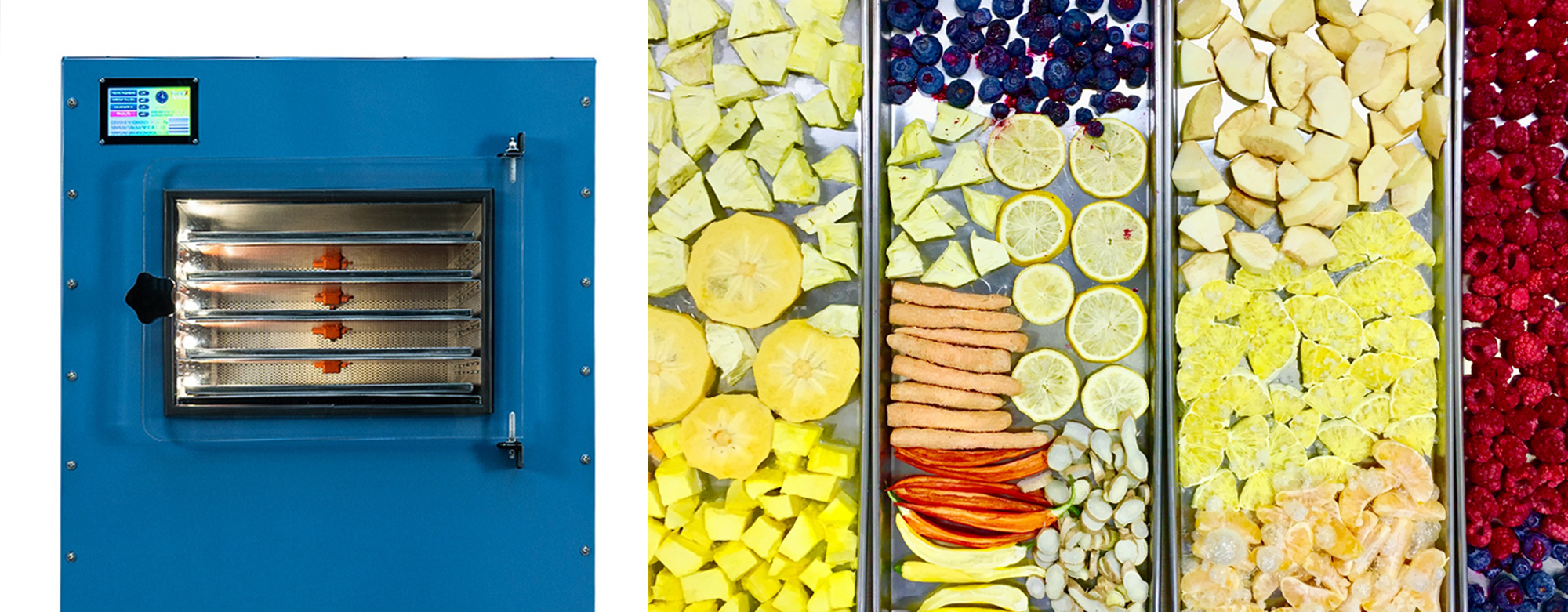

The project with acronym FrostWave concerns the development of a novel microwave assisted freeze drying device. The working medium in the cooling/freezing system of the freeze-dryer is a natural working fluid. Selected types of food of agricultural and sea origin are freeze-dried. More detailed information on the research conducted in the project can be found on the RESEARCH subpage.

The project is carried out by consortium formed by the Silesian University of Technology in Gliwice, the Gliwice company FrostX, the Norwegian University of Science and Technology in Trondheim and the SINTEF research institute in Trondheim. Information on the research team is available on the TEAM subpage.

The project is financed by the National Center for Research and Development (NCBiR) in the framework of the POLNOR project. People interested in the freeze-drying process can use this portal to perform a computer simulation of selected stages of the process. However, it requires registering on the CALCULATIONS subpage and filling in the form defining the data for calculations.

Motivations:

Currently, the advance freezing systems are required in order to guarantee long-term natural preservation and high quality of the stored food. Such systems are usually not easily accessible for small and medium food producers. Meanwhile, the food preservation and storage technology should be suitable and affordable for utilisation on the early stages of the food chain. Promising food preservation method that meets the aforementioned criterions is freeze-drying technology. In that method, the whole water content is removed from the processed food. In a result, the processed products do not require cooling during the transportation or storage. The nutrition value of these products is much higher compared to those frozen within most common techniques. The freeze-drying technology significantly improves the food safety and reduce food waste.

The novel microwave-assisted freeze-dryer developed within the FrostWave project will guarantee the high quality of the processed food and improved energy efficiency of the device. Therefore, the vacuum chamber and MW heating unit, as well as natural working fluid-based refrigeration system for the freeze-dryer will be carefully designed. Within such approach, the novel device will allow to significantly reduce power consumption and amount of the food waste comparing to the approach based on frozen food storage. Consequently, reduction of the greenhouse gases emission will impact the environmental aspects and social standards by an increase of resiliency of food storage in regions without access to a reliable power grid. Hence, the main objective of the FrostWave is to develop the state-of-the-art freeze-drying unit supported with microwave heating for new food value chains and food waste limitation.

Scientific publications in the project:

Journal papers:

- Edyta Piechnik, J. Smolka, M. Palacz, I. Tolstorebrov, T. M. Eikevik, M. Stebel, M. Haida, A. J. Nowak, A. Ciesielska, J. Bodys, Experimentally validated CFD-tool for a freezing simulation in a small-scale freeze-dryer, Journal of Food Engineeringl, 2023, 111888, ISSN 0260-8774. Read more...

- In preperation,

Conference papers:

- In preperation, Conference, bibliographic data. Read more...