Development of novel microwave-assisted freeze-drying unit combined with natural working fluid-based refrigeration system for agriculture and marine foods

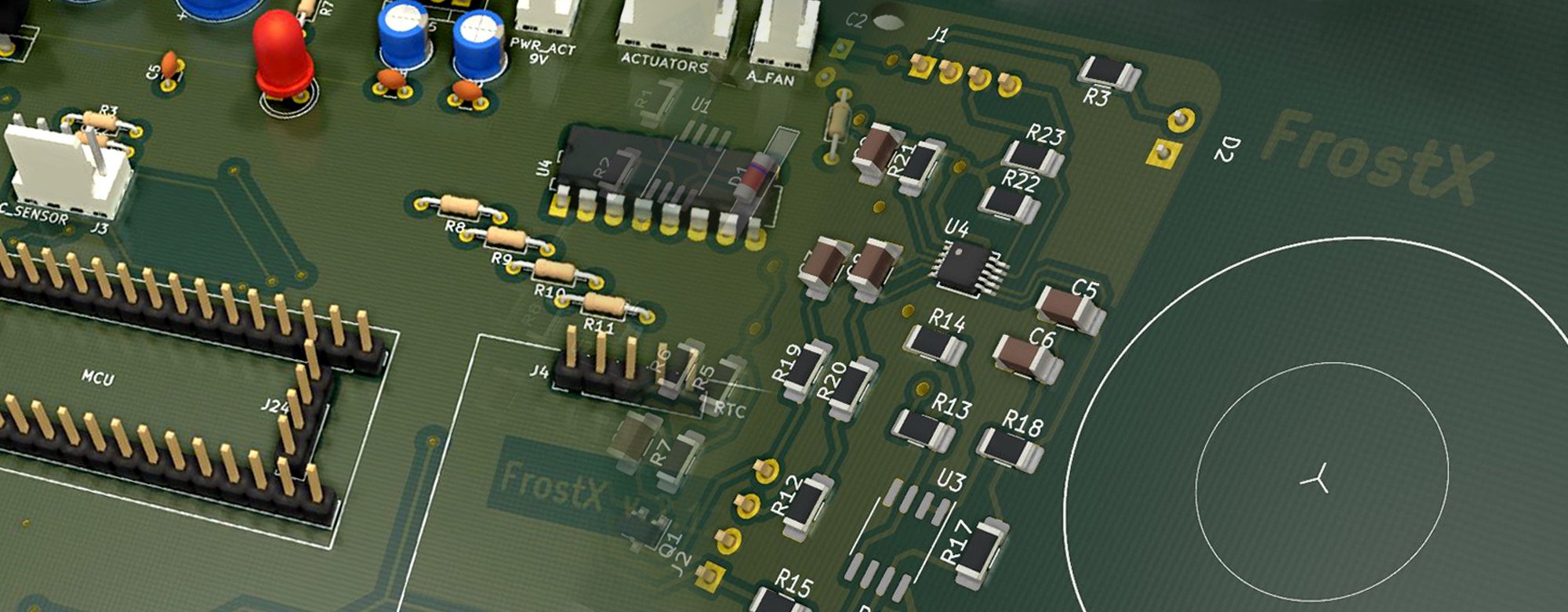

General description

The experimental investigation at the standard FD unit prepared by FrostX will be carried out to evaluate the temperature of the sampled food, delivered cold and inlet/outlet temperatures from the cryostat unit and the chamber pressure and temperature. Moreover, the electric power consumption will be measured to define the total power consumption of the reference unit. The test campaign will be defined for different types of food including agricultural and marine foods like:strawberries, herbs, cods, and shrimps that the most important products on the Polish and Norwegian market, respectively. All the tests will be carried out in the SUT laboratory where the test rigs of the hydrofluidisation freezing method and the natural R744 ejector-based refrigeration units are located.The collected experimental data will be used to evaluate the performance of the reference unit and also to validate the CFD model of the standard solution.

Device in the Lab

An utilisation of MW lyophilisation required to specify proper operating conditions for performance improvement and high food quality. Therefore, comparative tests on a standard MW-assisted vacuum freeze dryer will be performed in order to determine the best practice boundary conditions for the prototype unit. High vacuum lyophilisation is expensive to achieve. For this reason, the planned tests will reveal what kind of lyophilisation conditions are required in order fulfil product specifications and requirements. The test results will be used to critically review the specifications of the MW lyophilisator.

The MWFD prototype design will allow for the utilisation in small-scale enterprises due to the compact size , the food type selection, and substantially reduced power consumption of the unit. In addition, the prototyping of the unit performed at FrostX will be carried out considering safety operation due to the tight connection of pipes, high quality of welds and emergency shut-off switch system. As a result, the manufactured FD chamber will ensure high-quality food preservation by optimisation of the dehydration process. The location of the MW heater and the vacuum pump inside the prototype will be defined to minimise the size inside the unit casing.

The MWFD prototype integrated with the control system will be installed for a long-term operation at the area of the small-scale enterprise such as the confectionery or restaurant. The results obtained from the field- test campaign will allow for the performance evaluation and definition of real food preservation efficiency of the prototype unit. The proposed installation will be utilised for the food types required by the mentioned device user. The operation time will be defined from 3 months up to 6 months. During that long-term operation, the specific data will be collected:

- Dehydration efficiency and power consumption of the unit processes: freezing, vacuuming and heating

- Temperature inside the FD chamber

- Pressure and temperature of the refrigeration system

- Pressure at the vacuum pump inlet and the running capacity of the vacuum pump